Casting parts play a crucial role in various industries such as automotive, aerospace, construction, and more. As a result, the demand for high-quality casting parts has increased, and so has the number of manufacturers. With so many options available, it can be overwhelming to choose the right casting parts manufacturer for your specific needs.

1. Quality of Products

The first and foremost factor to consider while selecting a casting parts manufacturer is the quality of their products. The manufacturer should have a history of producing high-quality casting parts that meet industry standards and customer requirements. You can conduct thorough research by checking their certifications, quality control processes, and customer reviews.

2. Expertise and Experience

Experience and expertise are two essential factors that determine the skill and knowledge of a casting parts manufacturer. A manufacturer with years of experience will have a better understanding of the casting process, materials, and technologies. They will be able to provide valuable insights and suggestions to improve the design and functionality of the parts. Additionally, the expertise of the manufacturer also reflects in their ability to handle complex projects and meet specific requirements.

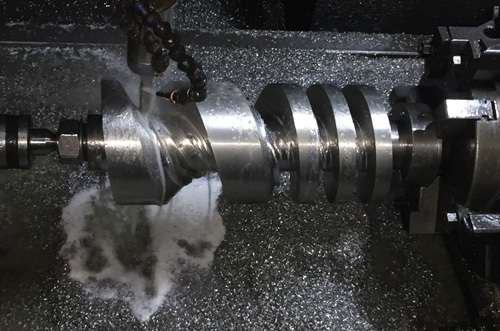

3. Manufacturing Capabilities

A reliable casting parts manufacturer should have the necessary equipment, technology, and resources to produce high-quality and precise parts. They should be able to provide a range of casting processes such as sand casting, investment casting, die casting, and more, to cater to different project requirements. Furthermore, they should also have the capacity to meet large-scale production demands and deliver the parts on time.

4. Customization and Prototyping Services

In many cases, standard parts may not meet your specific requirements, and you may need customized casting parts. Hence, it is important to choose a manufacturer who offers prototyping services and can help you develop a custom design. This will ensure that the final product meets your expectations and requirements.

5. Cost and Pricing Model

Cost is a crucial factor that influences the decision-making process of selecting a casting parts manufacturer. While it is important to opt for a cost-effective option, it is equally important to ensure that the quality of the parts is not compromised. You should conduct market research and compare the prices of different manufacturers to get an idea of the market rates.

6. Material Selection

The material used for casting parts plays a crucial role in their performance and durability. It is advisable to choose a manufacturer who offers a wide range of materials to choose from, such as aluminum, iron, bronze, and more.

7. Quality Control Processes

A reputable casting parts manufacturer should have strict quality control processes in place to ensure that the final product meets the required quality standards. They should have a team of skilled professionals who conduct regular inspections and checks at every stage of the manufacturing process to identify and rectify any potential defects.

8. Delivery and Logistics

The timely delivery of casting parts is crucial, especially when it comes to meeting project deadlines. Hence, it is essential to choose a manufacturer who has a reliable and efficient logistics system in place to ensure timely delivery of the parts. They should also have the necessary packaging and handling processes to ensure that the parts reach you in perfect condition.

9. Customer Service and Support

A reliable manufacturer should have a strong customer service and support system in place to address any queries or concerns you may have. They should be open to communication and provide timely updates on the progress of your project.

Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have metal hardware,CNC parts,casting parts,precision machining parts,etc.At the same time, we also have a long-term cooperative surface treatment,spining and stamping etc.plant.Our processing methods include: CNC Turning,Wire EDM,Casting,Riveting,Grinding,Stamping,Tapping, etc. Can handle materials such as Plastic,Copper,any types of alloy,Stainless Steel,Titanium,Brass,Carbon steel,Cold rolled sheet,Aluminum,Alloy,Steel Alloys,Chrome steel.

We are committed to offer high tech, precision, good quality products to our customers at competitive price. All of them are manufactured in our plant which can be controlled quality well. We believe honesty and customer service are the foundation of a successful business.We design, manufacture and assemble all kinds of different metal and plastic parts according to designs or drawings and requirements from customers.We have obtained CE, RoHS, GS, ISO9001 and other certifications.