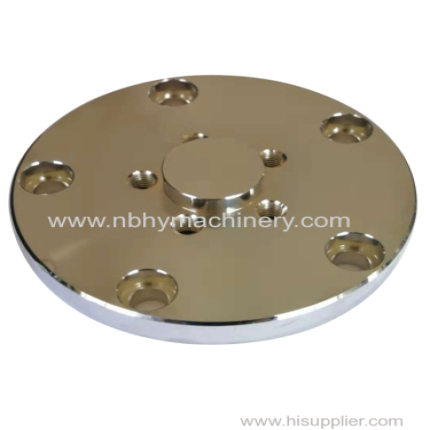

Ningbo Yinzhou Hongyong Machinery Factory is a professional manufacturer that supplies forging parts,casting parts,CNC parts,precision machining parts. It integrates OEM product analysis, rapid prototyping, sample production, mass production, and long-term after-sales service. We have precision machining machinery such as Punch press 6.3 to 160 T,Welding machine,Assembly line,Hydraulic bending machine,Polishing machine,Milling machine. Located in Ningbo City, adjacent to Ningbo Port and Shanghai Port, it has various raw material suppliers and resources.

With 10 years of experience in mechanical processing and other product exports, we have established a professional team covering technical support, batch production management, quality control, export packaging, and sales services. We have a dedicated testing and inspection department, as well as equipment such as Micrometer ID/OD,Thread gauge,Block gauge,Caliper digital,Granite Surface Plate,High gauge,Video measurement (profile projector),Coordinate measuring machine (CMM). Through years of experience, we have collaborated with many major clients both domestically and internationally, exporting our products to regions such as Asia,America,Europe, as well as countries such as the United States, France, Italy, and Morocco,Guinea,Tanzania,Central African Republic,Isle of Man.

china cnc machine parts technology is more accurate.Each equipment has professional worker to operate.

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

30% deposit ,70% payment aganist B/L

china cnc machine parts---FAQs Guide

With 10 years of experience in mechanical processing and other product exports, we have established a professional team covering technical support, batch production management, quality control, export packaging, and sales services. We have a dedicated testing and inspection department, as well as equipment such as Micrometer ID/OD,Thread gauge,Block gauge,Caliper digital,Granite Surface Plate,High gauge,Video measurement (profile projector),Coordinate measuring machine (CMM). Through years of experience, we have collaborated with many major clients both domestically and internationally, exporting our products to regions such as Asia,America,Europe, as well as countries such as the United States, France, Italy, and Morocco,Guinea,Tanzania,Central African Republic,Isle of Man.

china cnc machine parts technology is more accurate.Each equipment has professional worker to operate.

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

30% deposit ,70% payment aganist B/L

This is our workshop and equipment

china cnc machine parts---FAQs Guide

1.Are china cnc machine parts suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

Yes, china cnc machine parts can be suitable for applications in special environments and climatic conditions. Depending on the material used, CNC machining parts can be designed to be corrosion-resistant, heat-resistant, and/or waterproof. Additionally, CNC machining parts can be designed to be lightweight and durable, making them suitable for use in harsh environments.

2.Are china cnc machine parts suitable for high or low temperature environments, such as aerospace or polar applications?

yes.In the field of aerospace, CNC lathes can process various complex components and parts

3.What are the trends in digitization and automation of china cnc machine parts to improve production efficiency and quality control?

We are a professional china cnc machine parts company dedicated to providing high quality products and services.

1.Improvement in accuracy and efficiency

2.The development of intelligence

3.Transformation and popularization

4.Enhance connectivity

1.Improvement in accuracy and efficiency

2.The development of intelligence

3.Transformation and popularization

4.Enhance connectivity

4.How to carry out quality control and inspection during the production process of china cnc machine parts?

Our products & services cover a wide range of areas and meet the needs of different fields.

1. Control the accuracy of the machine tool

2. Monitor and test tool wear

3. Control the temperature during the machining process

4. Inspect the processed parts

1. Control the accuracy of the machine tool

2. Monitor and test tool wear

3. Control the temperature during the machining process

4. Inspect the processed parts

5.What is the production capacity of china cnc machine parts, and can they meet the needs of large-scale production?

china cnc machine parts are mainly suitable for the following occasions: batch production: CNC lathes are suitable for large-scale and continuous batch production.

6.What is the machining accuracy and repeatability of china cnc machine parts to achieve assembly and interchangeability?

For machine tools with general machining requirements, the repeated positioning accuracy is generally required to be less than or equal to 0.005mm.

7.How can china cnc machine parts meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

Before preparing the CNC turning process, we need to first confirm the geometric shape and size of the parts to be processed, which requires accurate calculations. For complex shaped parts, CAD software can be used for design and drawing, and then extract the contour and control lines of the parts to be processed. Through these control points, the machining path can be confirmed, and then the CNC machine tool plan and program can be set up