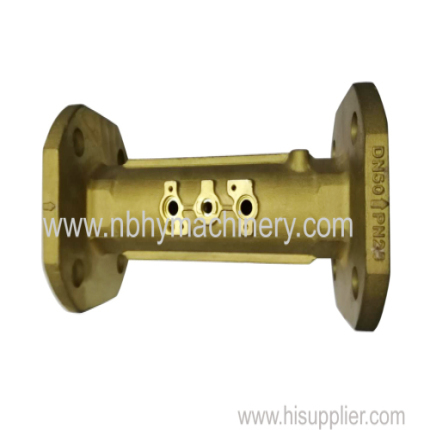

Alloy Machining Service Cnc Machining Parts

Product Description

Ningbo Yinzhou Hongyong Machinery Factory is a professional manufacturer that supplies casting parts,CNC parts,metal hardware,precision machining parts. It integrates OEM product analysis, rapid prototyping, sample production, mass production, and long-term after-sales service. We have precision machining machinery such as Welding machine,Laser cutting machine,Hydraulic bending machine,Assembly line,Polishing machine,Hydraulic shearer. Located in Ningbo City, adjacent to Ningbo Port and Shanghai Port, it has various raw material suppliers and resources.

With 10 years of experience in mechanical processing and other product exports, we have established a professional team covering technical support, batch production management, quality control, export packaging, and sales services. We have a dedicated testing and inspection department, as well as equipment such as Micrometer ID/OD,Thread gauge,Block gauge,Video measurement (profile projector),High gauge,Pin gauge,Coordinate measuring machine (CMM),Caliper digital. Through years of experience, we have collaborated with many major clients both domestically and internationally, exporting our products to regions such as Europe,Asia,Oceania, as well as countries such as the United States, France, Italy, and Bahamas, The,French Polynesia,Togo,Holy See (Vatican City),Burkina Faso.

alloy machining service cnc machining parts:

Customized Design

Sample Order Accepted

Short Delivery time

Competitive Prices

Long time quality Insurance

Professional after-sale services

QC System:100% inspection according to the MIL-STD-105E, ANSI ASQC Z1.4, ABC-STD-105, BS6001, ISO 2859, DIN 40080 before shipment.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

T/T 30% prepaid and balance paid before shipment for the first batch order

This is our workshop and equipment

alloy machining service cnc machining parts---FAQs Guide

1.What are the common materials used for alloy machining service cnc machining parts?

2.How do alloy machining service cnc machining parts manage supply chain and inventory to ensure timely delivery and production planning?

3.Are alloy machining service cnc machining parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

4.What are the product skill training options?

5.How to ensure that the surface finish and quality of alloy machining service cnc machining parts meet the specification requirements?

6.How can alloy machining service cnc machining parts cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

7.What is the research and development capability of the factory?

8.How do alloy machining service cnc machining parts handle the extrusion and removal processes of materials to meet design requirements?

9.How can alloy machining service cnc machining parts meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

10.What is the production capacity of alloy machining service cnc machining parts, and can they meet the needs of large-scale production?

11.Are there alloy machining service cnc machining parts suitable for parts with special shapes or complex structures?

12.How can we ensure our information should not let third party to see our design?

13.About alloy machining service cnc machining parts,Where can I get product&price information?

14.How can alloy machining service cnc machining parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

15.How do alloy machining service cnc machining parts handle the cutting and carving processes of materials to meet the requirements of complex parts?

16.As a alloy machining service cnc machining parts manufacturer,can you make custom parts based on my sample?

1.What are the common materials used for alloy machining service cnc machining parts?

Titanium, Aluminum, Stainless Steel, Copper/Brass, Iron, any types of alloy

2.How do alloy machining service cnc machining parts manage supply chain and inventory to ensure timely delivery and production planning?

We are centered on customers and always pay attention to customers' needs for alloy machining service cnc machining parts products.

1. Specify the warehousing standards for components

2. Warehousing of components

3. Review of component delivery notes

4. Quality inspection and acceptance

3.Are alloy machining service cnc machining parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

Yes, alloy machining service cnc machining parts can be suitable for applications under high temperature and pressure conditions. CNC machining parts can be made from a variety of materials, including metals such as stainless steel, aluminum, and titanium, which are all suitable for high temperature and pressure applications. Additionally, CNC machining parts can be designed to meet specific requirements, such as corrosion resistance, strength, and durability.

4.What are the product skill training options?

Our training options include:

1. Basic knowledge of CNC machining

2. CNC programming technology

3. Machining process and fixture design

4. Operating skills of CNC machining centers

5. Troubleshooting and maintenance

6. Safety operation and quality control

7. Application cases and practical operations

5.How to ensure that the surface finish and quality of alloy machining service cnc machining parts meet the specification requirements?

We are centered on customers and always pay attention to customers' needs for alloy machining service cnc machining parts products.

1.selecting appropriate cutting parameters is the key to controlling surface roughness and smoothness

2.the selection and grinding of cutting tools also play an important role in controlling surface roughness and smoothness

6.How can alloy machining service cnc machining parts cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

Reduce the cutting force to the minimum;It is to enhance the static rigidity of the tool system or fixture with the workpiece as much as possible

7.What is the research and development capability of the factory?

CNC machine tool manufacturers have innovated in the structural design of machine tools. They designed a more compact, stable, and highly rigid structure by analyzing the basic principles of mechanical cutting and the motion characteristics of machine tools. This structure can improve the rigidity and stability of the machine tool, reduce the vibration, noise, and heat generated during high-speed cutting, and thus improve the processing quality and efficiency.

8.How do alloy machining service cnc machining parts handle the extrusion and removal processes of materials to meet design requirements?

alloy machining service cnc machining parts use a variety of tools and techniques to handle the extrusion and removal processes of materials. Depending on the material and design requirements, the machining process may involve cutting, drilling, milling, grinding, and other operations. For example, a CNC milling machine can be used to cut away excess material from a workpiece, while a CNC lathe can be used to shape and form the material. Additionally, CNC machining can be used to create complex shapes and features, such as threads, grooves, and other intricate details.

9.How can alloy machining service cnc machining parts meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

Before preparing the CNC turning process, we need to first confirm the geometric shape and size of the parts to be processed, which requires accurate calculations. For complex shaped parts, CAD software can be used for design and drawing, and then extract the contour and control lines of the parts to be processed. Through these control points, the machining path can be confirmed, and then the CNC machine tool plan and program can be set up

10.What is the production capacity of alloy machining service cnc machining parts, and can they meet the needs of large-scale production?

alloy machining service cnc machining parts are mainly suitable for the following occasions: batch production: CNC lathes are suitable for large-scale and continuous batch production.

11.Are there alloy machining service cnc machining parts suitable for parts with special shapes or complex structures?

Yes, CNC machining is suitable for parts with special shapes or complex structures. CNC machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a block of material to create a part with a specific shape and size. CNC machining is ideal for producing parts with complex geometries and intricate details that would be difficult or impossible to produce with traditional manufacturing methods.

12.How can we ensure our information should not let third party to see our design?

We are willing to sign NDA effect by customer side local law and promising to keep customers data in high confidential level.

13.About alloy machining service cnc machining parts,Where can I get product&price information?

Send us e-mail , we will contact you as we receive your mail.

14.How can alloy machining service cnc machining parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

We have established a good reputation and reliable partnerships within the alloy machining service cnc machining parts industry.

1.detailed design and modeling of the parts are required

2.Programming is a very important step in the machining process of CNC machine tools

15.How do alloy machining service cnc machining parts handle the cutting and carving processes of materials to meet the requirements of complex parts?

We operate our alloy machining service cnc machining parts business with integrity and honesty.

1.Cleaning and inspection process

2.Measurement process

3.Adjusting the cutting space of the tool

16.As a alloy machining service cnc machining parts manufacturer,can you make custom parts based on my sample?

Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing forproduction.

Related Products

building cnc machine part 3

bulk cnc machined metal parts

bulk cnc machining aluminum part

bushings cnc machining stainless steel parts

camera cnc machining parts

camera on cnc machine measure part

car cnc machining parts

car parts machining custom cnc

Related Links

Category: Other products