China Brass Cnc Machined Parts

Product Description

Ningbo Yinzhou Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have precision machining parts,metal hardware,CNC parts,forging parts,etc.At the same time, we also have a long-term cooperative surface treatment,spining and stamping etc.plant.Our processing methods include: Riveting,Gear cutting,Tapping,Drilling,Grinding,Forging,Stamping, etc. Can handle materials such as Chrome steel,Copper,Cold rolled sheet,Nylon,Steel Alloys,Titanium,Plastic,any types of alloy,Stainless Steel,Brass,Carbon steel,Iron.

We are committed to offer high tech, precision, good quality products to our customers at competitive price. All of them are manufactured in our plant which can be controlled quality well. We believe honesty and customer service are the foundation of a successful business.We design, manufacture and assemble all kinds of different metal and plastic parts according to designs or drawings and requirements from customers.We have obtained CE, RoHS, GS, ISO9001 and other certifications.

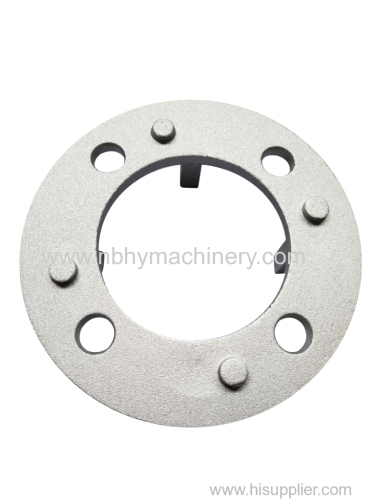

china brass cnc machined parts:Custom Turning Machining Spare Part CNC Machined Parts

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

30% deposit ,70% payment aganist B/L

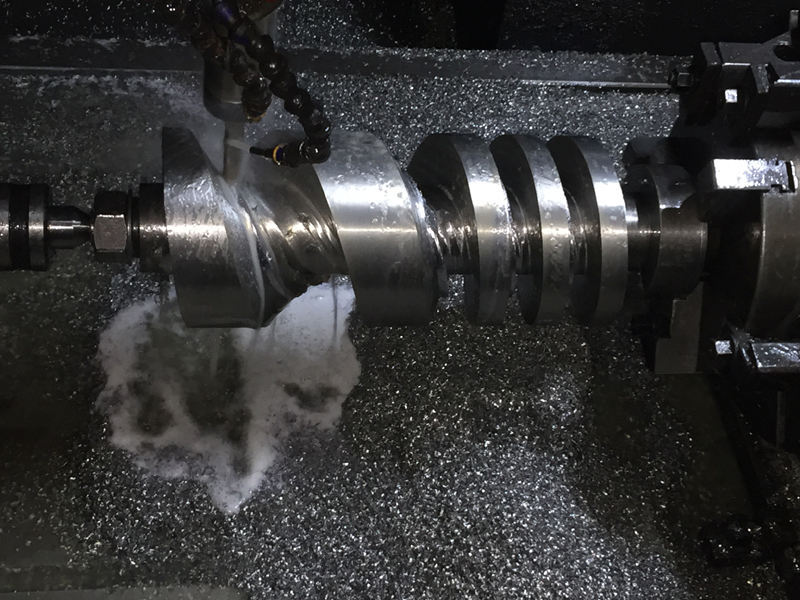

This is our workshop and equipment

china brass cnc machined parts---FAQs Guide

1.How can china brass cnc machined parts cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

2.Are china brass cnc machined parts suitable for high or low temperature environments, such as aerospace or polar applications?

3.How can china brass cnc machined parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

4.How does the manufacturing process and process of china brass cnc machined parts affect their quality and accuracy?

5.Are china brass cnc machined parts suitable for special surface treatment or coating requirements? Such as wear resistance or corrosion resistance

6.What is the role of CNC machining parts in the manufacturing industry?

7.How can china brass cnc machined parts meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

8.Can the size and shape of china brass cnc machined parts be customized according to needs?

9.Are china brass cnc machined parts suitable for safety critical applications with high precision and reliability requirements, such as automotive braking systems or aviation navigation?

10.What is the accuracy and repeatability of china brass cnc machined parts?

11.Are china brass cnc machined parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

1.How can china brass cnc machined parts cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

Reduce the cutting force to the minimum;It is to enhance the static rigidity of the tool system or fixture with the workpiece as much as possible

2.Are china brass cnc machined parts suitable for high or low temperature environments, such as aerospace or polar applications?

yes.In the field of aerospace, CNC lathes can process various complex components and parts

3.How can china brass cnc machined parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

During the machining process, attention should always be paid to the wear of the cutting tools, and severely worn cutting tools should be replaced in a timely manner to ensure the machining effect.

When adjusting cutting parameters, comprehensive consideration should be given to factors such as material hardness, cutting depth, and the shape of the workpiece being processed to achieve the best effect.

4.How does the manufacturing process and process of china brass cnc machined parts affect their quality and accuracy?

The manufacturing process and process of china brass cnc machined parts affect their quality and accuracy in several ways. First, the accuracy of the CNC machining process is dependent on the quality of the raw materials used. If the raw materials are of poor quality, the accuracy of the machined parts will be compromised. Second, the accuracy of the machined parts is also affected by the accuracy of the CNC machine itself. If the machine is not properly calibrated or maintained, the accuracy of the machined parts will be compromised. Finally, the accuracy of the machined parts is also affected by the skill of the operator. If the operator is not experienced or trained properly, the accuracy of the machined parts will be compromised.

5.Are china brass cnc machined parts suitable for special surface treatment or coating requirements? Such as wear resistance or corrosion resistance

Yes, china brass cnc machined parts are suitable for special surface treatment or coating requirements. Depending on the application, CNC machined parts can be treated with a variety of coatings, such as anodizing, electroplating, powder coating, and painting. These coatings can provide additional protection against wear and corrosion.

6.What is the role of CNC machining parts in the manufacturing industry?

Improving machining accuracy and quality,Improve production efficiency and efficiency

7.How can china brass cnc machined parts meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

Before preparing the CNC turning process, we need to first confirm the geometric shape and size of the parts to be processed, which requires accurate calculations. For complex shaped parts, CAD software can be used for design and drawing, and then extract the contour and control lines of the parts to be processed. Through these control points, the machining path can be confirmed, and then the CNC machine tool plan and program can be set up

8.Can the size and shape of china brass cnc machined parts be customized according to needs?

Yes, china brass cnc machined parts can be customized according to the customer's needs. CNC machining can produce parts in a variety of sizes and shapes, including complex geometries. The customer can provide a design or drawing of the desired part, and the CNC machining shop can use the design to create the part.

9.Are china brass cnc machined parts suitable for safety critical applications with high precision and reliability requirements, such as automotive braking systems or aviation navigation?

Yes, china brass cnc machined parts can be suitable for safety critical applications with high precision and reliability requirements. CNC machining is a highly accurate and repeatable process that can produce parts with tight tolerances and high levels of precision. CNC machining can also be used to produce parts with complex geometries and intricate details, making it suitable for a wide range of applications.

10.What is the accuracy and repeatability of china brass cnc machined parts?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

1.The smaller the difference between the actual position of parts or tools and the standard position (theoretical position, ideal position), the higher the accuracy. It is a prerequisite for ensuring the machining accuracy of parts.

2.The consistency of continuous results obtained by machining a batch of parts under the same conditions (on the same CNC machine tool, with different operating methods and using the same part program).

11.Are china brass cnc machined parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

Yes, china brass cnc machined parts can be suitable for applications under high temperature and pressure conditions. CNC machining parts can be made from a variety of materials, including metals such as stainless steel, aluminum, and titanium, which are all suitable for high temperature and pressure applications. Additionally, CNC machining parts can be designed to meet specific requirements, such as corrosion resistance, strength, and durability.

Related Products

cnc machine for metal

cnc machined parts Hongyong Machinery

cnc machine milling Hongyong Machinery

custom cnc machining Hongyong Machinery

custom cnc milling parts

custom cnc parts hongyongmachinery

custom machine hongyong machinery

machined parts Hongyong Machinery

Related Links

Category: Other products