Aluminum Parts Cnc Custom Machining

Product Description

Ningbo Yinzhou Hongyong Machinery Factory is a professional supplier of forging parts,casting parts,CNC parts,metal hardware and other products. We have been committed to providing design, development, production, and services. With advanced equipment, strict testing methods, comprehensive internal control systems, and excellent after-sales service, we can provide the best OEM and ODM services according to customer requirements.

We currently have processing machinery such as Milling machine,Hydraulic bending machine,Polishing machine,Laser cutting machine,Hydraulic shearer,Welding machine. The product can be used in industries such as aerospace industry,auto and motorcycle accessory,oil&gas exploration,hardware tool,home appliance,automation industry,medical device industry. We have obtained certifications such as CE, RoHS, GS, ISO9001. As an export-oriented enterprise, we are committed to exploring markets in countries such as the United States, Canada, the United Kingdom, and United Arab Emirates,South Korea,Timor-Leste,Seychelles,India,Laos.

aluminum parts cnc custom machining technology is more accurate.Each equipment has professional worker to operate.

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

30% deposit ,70% payment aganist B/L

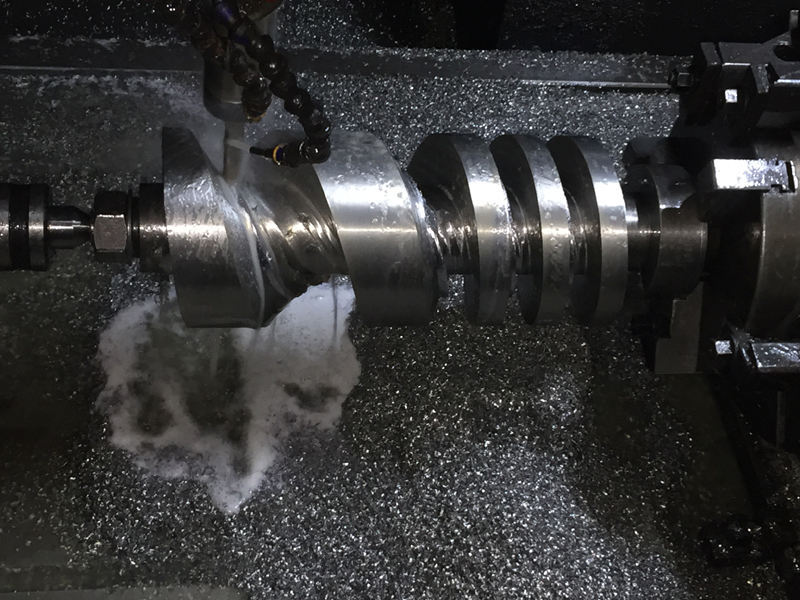

This is our workshop and equipment

aluminum parts cnc custom machining---FAQs Guide

1.As a aluminum parts cnc custom machining manufacturer,what is the material?

2.How can we ensure our information should not let third party to see our design?

3.Are there aluminum parts cnc custom machining suitable for the manufacturing of special precision measurement and calibration equipment, such as microscopes or particle size analyzers?

4.How to ensure the dimensional accuracy of aluminum parts cnc custom machining to meet assembly and splicing requirements?

5.How about the maintainability and spare parts supply of aluminum parts cnc custom machining?

6.How do aluminum parts cnc custom machining handle the extrusion and removal processes of materials to meet design requirements?

7.Can the size and shape of aluminum parts cnc custom machining be customized according to needs?

8.What are the advantages of aluminum parts cnc custom machining?

9.How can aluminum parts cnc custom machining meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

10.Are aluminum parts cnc custom machining suitable for high or low temperature environments, such as aerospace or polar applications?

11.What is the strength and rigidity of aluminum parts cnc custom machining, suitable for high load applications?

12.About aluminum parts cnc custom machining,Where can I get product&price information?

13.How does the manufacturing process and process of aluminum parts cnc custom machining affect their quality and accuracy?

14.Are aluminum parts cnc custom machining suitable for safety critical applications with high precision and reliability requirements, such as automotive braking systems or aviation navigation?

15.How can aluminum parts cnc custom machining cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

1.As a aluminum parts cnc custom machining manufacturer,what is the material?

Plastics we can manufacture are ABS, PC, PP, PA, PA+GF, PTFE etc, metals are aluminum, stainless steel, brass, copper etc.

2.How can we ensure our information should not let third party to see our design?

We are willing to sign NDA effect by customer side local law and promising to keep customers data in high confidential level.

3.Are there aluminum parts cnc custom machining suitable for the manufacturing of special precision measurement and calibration equipment, such as microscopes or particle size analyzers?

Yes, aluminum parts cnc custom machining can be used to manufacture special precision measurement and calibration equipment. CNC machining is a process that uses computer numerical control (CNC) machines to cut and shape materials into precise shapes and sizes. CNC machining can be used to create parts with tight tolerances and intricate details, making it ideal for precision measurement and calibration equipment.

4.How to ensure the dimensional accuracy of aluminum parts cnc custom machining to meet assembly and splicing requirements?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

1. Use high-precision processing equipment and tools.

2. Strictly control the processing process.

3. Use appropriate testing for measurement work.

4. Conduct pre assembly coordination testing and adjustments

5.How about the maintainability and spare parts supply of aluminum parts cnc custom machining?

When the CNC system is not in use for a long time, the maintenance work should pay attention to the following two aspects:

1.the CNC system should be regularly powered on and running idle, so that the heat from the electronic and electrical components of the CNC system can be used to dissipate the moisture inside the CNC cabinet

2.The normal supply of spare parts is a guarantee measure to ensure the normal and uninterrupted operation of the system. Our company will provide spare parts for auxiliary equipment during the warranty period and random spare parts during equipment installation and debugging

6.How do aluminum parts cnc custom machining handle the extrusion and removal processes of materials to meet design requirements?

aluminum parts cnc custom machining use a variety of tools and techniques to handle the extrusion and removal processes of materials. Depending on the material and design requirements, the machining process may involve cutting, drilling, milling, grinding, and other operations. For example, a CNC milling machine can be used to cut away excess material from a workpiece, while a CNC lathe can be used to shape and form the material. Additionally, CNC machining can be used to create complex shapes and features, such as threads, grooves, and other intricate details.

7.Can the size and shape of aluminum parts cnc custom machining be customized according to needs?

Yes, aluminum parts cnc custom machining can be customized according to the customer's needs. CNC machining can produce parts in a variety of sizes and shapes, including complex geometries. The customer can provide a design or drawing of the desired part, and the CNC machining shop can use the design to create the part.

8.What are the advantages of aluminum parts cnc custom machining?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced aluminum parts cnc custom machining products.

1. Highly precise

2. High efficiency

3. Strong flexibility

4. Simple operation

5. Stable quality

6. High productivity

7. Wide processing range

8. Cost saving

9. Reliable and stable

9.How can aluminum parts cnc custom machining meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

Before preparing the CNC turning process, we need to first confirm the geometric shape and size of the parts to be processed, which requires accurate calculations. For complex shaped parts, CAD software can be used for design and drawing, and then extract the contour and control lines of the parts to be processed. Through these control points, the machining path can be confirmed, and then the CNC machine tool plan and program can be set up

10.Are aluminum parts cnc custom machining suitable for high or low temperature environments, such as aerospace or polar applications?

yes.In the field of aerospace, CNC lathes can process various complex components and parts

11.What is the strength and rigidity of aluminum parts cnc custom machining, suitable for high load applications?

The ability of metal materials to resist elastic deformation under stress and The ability of metal materials to resist plastic deformation and fracture under external forces.

12.About aluminum parts cnc custom machining,Where can I get product&price information?

Send us e-mail , we will contact you as we receive your mail.

13.How does the manufacturing process and process of aluminum parts cnc custom machining affect their quality and accuracy?

The manufacturing process and process of aluminum parts cnc custom machining affect their quality and accuracy in several ways. First, the accuracy of the CNC machining process is dependent on the quality of the raw materials used. If the raw materials are of poor quality, the accuracy of the machined parts will be compromised. Second, the accuracy of the machined parts is also affected by the accuracy of the CNC machine itself. If the machine is not properly calibrated or maintained, the accuracy of the machined parts will be compromised. Finally, the accuracy of the machined parts is also affected by the skill of the operator. If the operator is not experienced or trained properly, the accuracy of the machined parts will be compromised.

14.Are aluminum parts cnc custom machining suitable for safety critical applications with high precision and reliability requirements, such as automotive braking systems or aviation navigation?

Yes, aluminum parts cnc custom machining can be suitable for safety critical applications with high precision and reliability requirements. CNC machining is a highly accurate and repeatable process that can produce parts with tight tolerances and high levels of precision. CNC machining can also be used to produce parts with complex geometries and intricate details, making it suitable for a wide range of applications.

15.How can aluminum parts cnc custom machining cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

We have established a good reputation and reliable partnerships within the aluminum parts cnc custom machining industry.

1.detailed design and modeling of the parts are required

2.Programming is a very important step in the machining process of CNC machine tools

Related Products

auto cnc machining parts

auto part cnc machining

auto parts cnc casting machining parts

automotive part cnc machining

basic parts of cnc milling machine

benchtop cnc milling machine part

bicycle milling cnc machining parts

bicycle parts cnc machining

Related Links

Category: Other products