China 5 Axis Cnc Machining Car Parts

Product Description

Hongyong Machinery is an enterprise that produces forging parts,metal hardware,CNC parts,casting parts, with complete testing equipment and strong technical strength. Our products have a wide variety, excellent quality, reasonable prices, and are widely used in industries such as automation industry,Power and energy,auto and motorcycle accessory,hardware tool,machinery accessory,aerospace industry,oil&gas exploration. We have obtained certifications such as CE, RoHS, GS, ISO9001.

Our processing methods mainly include Gear cutting,CNC Turning,Riveting,Drilling,Tapping,Wire EDM,Casting, etc. Having surface treatment technologies such as Powder coating,heat treatment,Titanium nitriding,Zinc plating,Sandblasting,Vacuum plating,hardening,plating,polishing,Thermal treatment,Oxidation,Ion nitriding,Passivation. At the same time, we provide OEM services. The main export markets include North America, Western Europe, Eastern Europe, South America, Southeast Asia, East Asia, etc. Our payment methods include wire transfer, letter of credit, and payment against documents. Our goal is to continuously improve quality and pursue customer satisfaction.

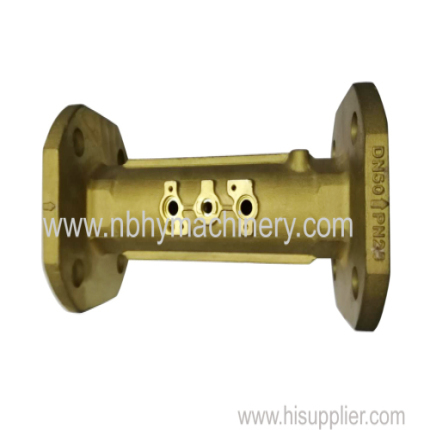

china 5 axis cnc machining car parts:

Customized Design

Sample Order Accepted

Short Delivery time

Competitive Prices

Long time quality Insurance

Professional after-sale services

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

30% deposit ,70% payment aganist B/L

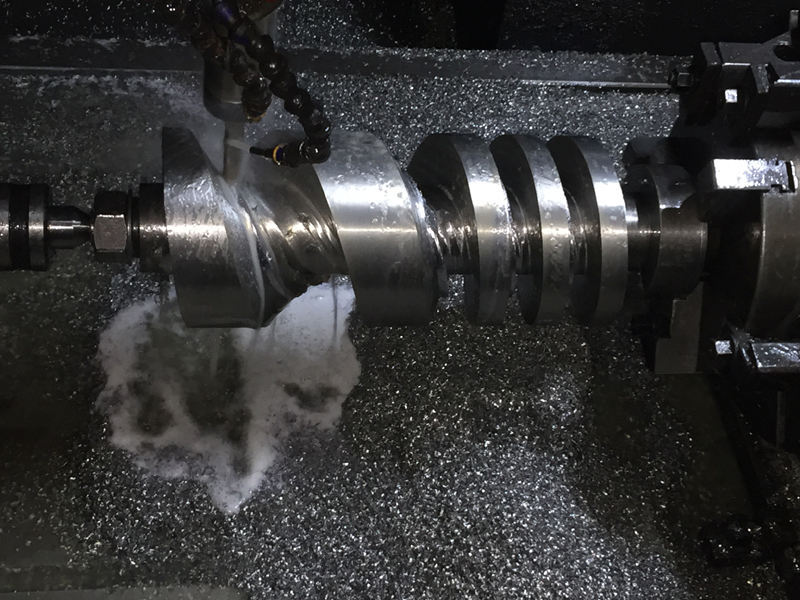

This is our workshop and equipment

china 5 axis cnc machining car parts---FAQs Guide

1.What is the strength and rigidity of china 5 axis cnc machining car parts, suitable for high load applications?

2.About china 5 axis cnc machining car parts,Where can I get product&price information?

3.As a china 5 axis cnc machining car parts manufacturer,can you make custom parts based on my sample?

4.What is the data collection and monitoring function of china 5 axis cnc machining car parts to improve production traceability and control?

5.About china 5 axis cnc machining car parts,How about the lead time?

6.Are china 5 axis cnc machining car parts suitable for special surface treatment or coating requirements? Such as wear resistance or corrosion resistance

7.What is the research and development capability of the factory?

8.What is the cleaning and maintenance process for china 5 axis cnc machining car parts to ensure equipment hygiene and performance?

9.Is china 5 axis cnc machining car parts suitable for applications in high-speed motion and vibration environments, such as automotive engines or machine tools?

10.How can china 5 axis cnc machining car parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

11.How to ensure the dimensional accuracy of china 5 axis cnc machining car parts to meet assembly and splicing requirements?

12.About china 5 axis cnc machining car parts,can I get a quote without drawings?

13.As a china 5 axis cnc machining car parts manufacturer,can you provide one-stop service including of material,processing,finish,assembly etc?

14.What is the role of CNC machining parts in the manufacturing industry?

1.What is the strength and rigidity of china 5 axis cnc machining car parts, suitable for high load applications?

The ability of metal materials to resist elastic deformation under stress and The ability of metal materials to resist plastic deformation and fracture under external forces.

2.About china 5 axis cnc machining car parts,Where can I get product&price information?

Send us e-mail , we will contact you as we receive your mail.

3.As a china 5 axis cnc machining car parts manufacturer,can you make custom parts based on my sample?

Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing forproduction.

4.What is the data collection and monitoring function of china 5 axis cnc machining car parts to improve production traceability and control?

We focus on providing high china 5 axis cnc machining car parts quality products and services.

1.Collecting various parameters including machine tool feed, spindle speed, temperature, vibration, current, etc., to achieve comprehensive and accurate data collection.

2.Through real-time monitoring and control, abnormal situations during machine tool processing can be detected in a timely manner, and adjustments can be made to improve processing stability and accuracy.

5.About china 5 axis cnc machining car parts,How about the lead time?

It depends on quantity, generally around 20-30 days after receipt of deposit (may vary depending on specific items and item quantities)

6.Are china 5 axis cnc machining car parts suitable for special surface treatment or coating requirements? Such as wear resistance or corrosion resistance

Yes, china 5 axis cnc machining car parts are suitable for special surface treatment or coating requirements. Depending on the application, CNC machined parts can be treated with a variety of coatings, such as anodizing, electroplating, powder coating, and painting. These coatings can provide additional protection against wear and corrosion.

7.What is the research and development capability of the factory?

CNC machine tool manufacturers have innovated in the structural design of machine tools. They designed a more compact, stable, and highly rigid structure by analyzing the basic principles of mechanical cutting and the motion characteristics of machine tools. This structure can improve the rigidity and stability of the machine tool, reduce the vibration, noise, and heat generated during high-speed cutting, and thus improve the processing quality and efficiency.

8.What is the cleaning and maintenance process for china 5 axis cnc machining car parts to ensure equipment hygiene and performance?

We are centered on customers and always pay attention to customers' needs for china 5 axis cnc machining car parts products.

1.Strictly follow the operating rules

2.Preventing overheating of CNC devices

3.Regularly monitor the grid voltage of CNC devices

4.Prevent dust from entering the CNC device 4Regular inspection and replacement of storage batteries.

5.Maintenance of CNC systems when not in use for a long time

9.Is china 5 axis cnc machining car parts suitable for applications in high-speed motion and vibration environments, such as automotive engines or machine tools?

Yes, china 5 axis cnc machining car parts are suitable for applications in high-speed motion and vibration environments. CNC machining parts are designed to be precise and durable, making them ideal for use in high-speed and vibration environments. CNC machining parts are also able to withstand high temperatures and pressures, making them suitable for use in automotive engines and machine tools.

10.How can china 5 axis cnc machining car parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

During the machining process, attention should always be paid to the wear of the cutting tools, and severely worn cutting tools should be replaced in a timely manner to ensure the machining effect.

When adjusting cutting parameters, comprehensive consideration should be given to factors such as material hardness, cutting depth, and the shape of the workpiece being processed to achieve the best effect.

11.How to ensure the dimensional accuracy of china 5 axis cnc machining car parts to meet assembly and splicing requirements?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

1. Use high-precision processing equipment and tools.

2. Strictly control the processing process.

3. Use appropriate testing for measurement work.

4. Conduct pre assembly coordination testing and adjustments

12.About china 5 axis cnc machining car parts,can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

13.As a china 5 axis cnc machining car parts manufacturer,can you provide one-stop service including of material,processing,finish,assembly etc?

Yes,we can.

14.What is the role of CNC machining parts in the manufacturing industry?

Improving machining accuracy and quality,Improve production efficiency and efficiency

Related Products

3d printedable cnc machine parts

4 axis cnc lathe machining parts

4 axis cnc machining aluminum parts

4 axis cnc machining parts

4 axis cnc milling machine parts

5 axis car lathe parts cnc machining

5 axis cnc machine gun parts

5 axis cnc machine parts

Related Links

Category: Other products