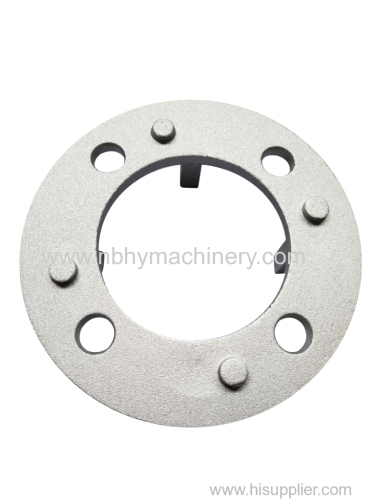

China Anodized Cnc Machining Parts

Product Description

Ningbo Yinzhou Hongyong Machinery Factory is a professional manufacturer that supplies forging parts,precision machining parts,CNC parts,casting parts. It integrates OEM product analysis, rapid prototyping, sample production, mass production, and long-term after-sales service. We have precision machining machinery such as Polishing machine,Hydraulic bending machine,Punch press 6.3 to 160 T,Milling machine,Welding machine,Hydraulic shearer. Located in Ningbo City, adjacent to Ningbo Port and Shanghai Port, it has various raw material suppliers and resources.

With 10 years of experience in mechanical processing and other product exports, we have established a professional team covering technical support, batch production management, quality control, export packaging, and sales services. We have a dedicated testing and inspection department, as well as equipment such as Block gauge,Video measurement (profile projector),Pin gauge,High gauge,Granite Surface Plate,Thread gauge,Micrometer ID/OD,Coordinate measuring machine (CMM). Through years of experience, we have collaborated with many major clients both domestically and internationally, exporting our products to regions such as Oceania,Europe,America, as well as countries such as the United States, France, Italy, and British Virgin Islands,Senegal,Japan,Mali,Tunisia,Western Sahara.

china anodized cnc machining parts:

Machine: 3/4/5 axis CNC Machining Center

Roughness: Ra0.2-Ra3.2

Tolerance: 0.005~0.05mm or refer to drawings strictly

Main Process: Turning / Milling

QC System:100% inspection according to the MIL-STD-105E, ANSI ASQC Z1.4, ABC-STD-105, BS6001, ISO 2859, DIN 40080 before shipment.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

30% deposit ,70% payment aganist B/L

This is our workshop and equipment

china anodized cnc machining parts---FAQs Guide

1.Are china anodized cnc machining parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

2.How can china anodized cnc machining parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

3.How can we ensure our information should not let third party to see our design?

4.About china anodized cnc machining parts,How about the lead time?

5.Are china anodized cnc machining parts suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

6.How does the manufacturing process and process of china anodized cnc machining parts affect their quality and accuracy?

7.How to ensure that the surface finish and quality of china anodized cnc machining parts meet the specification requirements?

8.How do china anodized cnc machining parts handle the cutting and carving processes of materials to meet the requirements of complex parts?

9.How about the maintainability and spare parts supply of china anodized cnc machining parts?

10.How do china anodized cnc machining parts manage supply chain and inventory to ensure timely delivery and production planning?

11.How can china anodized cnc machining parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

12.What are the trends in digitization and automation of china anodized cnc machining parts to improve production efficiency and quality control?

13.How does the selection of machine tools and cutting tools for china anodized cnc machining parts affect machining speed and quality?

14.What is the cleaning and maintenance process for china anodized cnc machining parts to ensure equipment hygiene and performance?

15.How can china anodized cnc machining parts meet the needs of rapid prototype manufacturing and small batch production?

1.Are china anodized cnc machining parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

Yes, china anodized cnc machining parts can be suitable for applications under high temperature and pressure conditions. CNC machining parts can be made from a variety of materials, including metals such as stainless steel, aluminum, and titanium, which are all suitable for high temperature and pressure applications. Additionally, CNC machining parts can be designed to meet specific requirements, such as corrosion resistance, strength, and durability.

2.How can china anodized cnc machining parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

During the machining process, attention should always be paid to the wear of the cutting tools, and severely worn cutting tools should be replaced in a timely manner to ensure the machining effect.

When adjusting cutting parameters, comprehensive consideration should be given to factors such as material hardness, cutting depth, and the shape of the workpiece being processed to achieve the best effect.

3.How can we ensure our information should not let third party to see our design?

We are willing to sign NDA effect by customer side local law and promising to keep customers data in high confidential level.

4.About china anodized cnc machining parts,How about the lead time?

It depends on quantity, generally around 20-30 days after receipt of deposit (may vary depending on specific items and item quantities)

5.Are china anodized cnc machining parts suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

Yes, china anodized cnc machining parts can be suitable for applications in special environments and climatic conditions. Depending on the material used, CNC machining parts can be designed to be corrosion-resistant, heat-resistant, and/or waterproof. Additionally, CNC machining parts can be designed to be lightweight and durable, making them suitable for use in harsh environments.

6.How does the manufacturing process and process of china anodized cnc machining parts affect their quality and accuracy?

The manufacturing process and process of china anodized cnc machining parts affect their quality and accuracy in several ways. First, the accuracy of the CNC machining process is dependent on the quality of the raw materials used. If the raw materials are of poor quality, the accuracy of the machined parts will be compromised. Second, the accuracy of the machined parts is also affected by the accuracy of the CNC machine itself. If the machine is not properly calibrated or maintained, the accuracy of the machined parts will be compromised. Finally, the accuracy of the machined parts is also affected by the skill of the operator. If the operator is not experienced or trained properly, the accuracy of the machined parts will be compromised.

7.How to ensure that the surface finish and quality of china anodized cnc machining parts meet the specification requirements?

We are centered on customers and always pay attention to customers' needs for china anodized cnc machining parts products.

1.selecting appropriate cutting parameters is the key to controlling surface roughness and smoothness

2.the selection and grinding of cutting tools also play an important role in controlling surface roughness and smoothness

8.How do china anodized cnc machining parts handle the cutting and carving processes of materials to meet the requirements of complex parts?

We operate our china anodized cnc machining parts business with integrity and honesty.

1.Cleaning and inspection process

2.Measurement process

3.Adjusting the cutting space of the tool

9.How about the maintainability and spare parts supply of china anodized cnc machining parts?

When the CNC system is not in use for a long time, the maintenance work should pay attention to the following two aspects:

1.the CNC system should be regularly powered on and running idle, so that the heat from the electronic and electrical components of the CNC system can be used to dissipate the moisture inside the CNC cabinet

2.The normal supply of spare parts is a guarantee measure to ensure the normal and uninterrupted operation of the system. Our company will provide spare parts for auxiliary equipment during the warranty period and random spare parts during equipment installation and debugging

10.How do china anodized cnc machining parts manage supply chain and inventory to ensure timely delivery and production planning?

We are centered on customers and always pay attention to customers' needs for china anodized cnc machining parts products.

1. Specify the warehousing standards for components

2. Warehousing of components

3. Review of component delivery notes

4. Quality inspection and acceptance

11.How can china anodized cnc machining parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

We have established a good reputation and reliable partnerships within the china anodized cnc machining parts industry.

1.detailed design and modeling of the parts are required

2.Programming is a very important step in the machining process of CNC machine tools

12.What are the trends in digitization and automation of china anodized cnc machining parts to improve production efficiency and quality control?

We are a professional china anodized cnc machining parts company dedicated to providing high quality products and services.

1.Improvement in accuracy and efficiency

2.The development of intelligence

3.Transformation and popularization

4.Enhance connectivity

13.How does the selection of machine tools and cutting tools for china anodized cnc machining parts affect machining speed and quality?

We have been working hard to improve service quality and meet customer needs.

1.Ensure the selection of appropriate cutting tools, and determine the type and specifications of the cutting tools based on the processing materials and requirements. Regularly inspect and replace severely worn tools to maintain their sharpness and work efficiency

2.Ensure that cutting parameters (such as cutting speed, feed rate, and cutting depth) are set reasonably to adapt to different machining tasks and materials

3.The fixation of the tool and the clamping state of the workpiece also have an impact on the tool speed

4.Regular maintenance and upkeep of CNC machine tools is also crucial for adjusting tool speed

14.What is the cleaning and maintenance process for china anodized cnc machining parts to ensure equipment hygiene and performance?

We are centered on customers and always pay attention to customers' needs for china anodized cnc machining parts products.

1.Strictly follow the operating rules

2.Preventing overheating of CNC devices

3.Regularly monitor the grid voltage of CNC devices

4.Prevent dust from entering the CNC device 4Regular inspection and replacement of storage batteries.

5.Maintenance of CNC systems when not in use for a long time

15.How can china anodized cnc machining parts meet the needs of rapid prototype manufacturing and small batch production?

We are centered on customers and always pay attention to customers' needs for china anodized cnc machining parts products.

1.When we use CNC for small batch processing, we need to control the drilling of components well

2.When we use CNC for small batch processing, we need to control the turning of components well

3.When we use CNC for small batch processing, we need to control the milling and cutting angles of the components

4.When we use CNC for small batch processing, we need to control the angle of the slotting process of the components

Related Products

custom cnc machining Hongyong Machinery

custom cnc milling parts

custom cnc parts hongyongmachinery

custom machine hongyong machinery

machined parts Hongyong Machinery

Metal CNC Hongyong Machinery

c&c machining Hongyong Machinery

cnc cutting service hongyong machinery

Related Links

Category: Other products